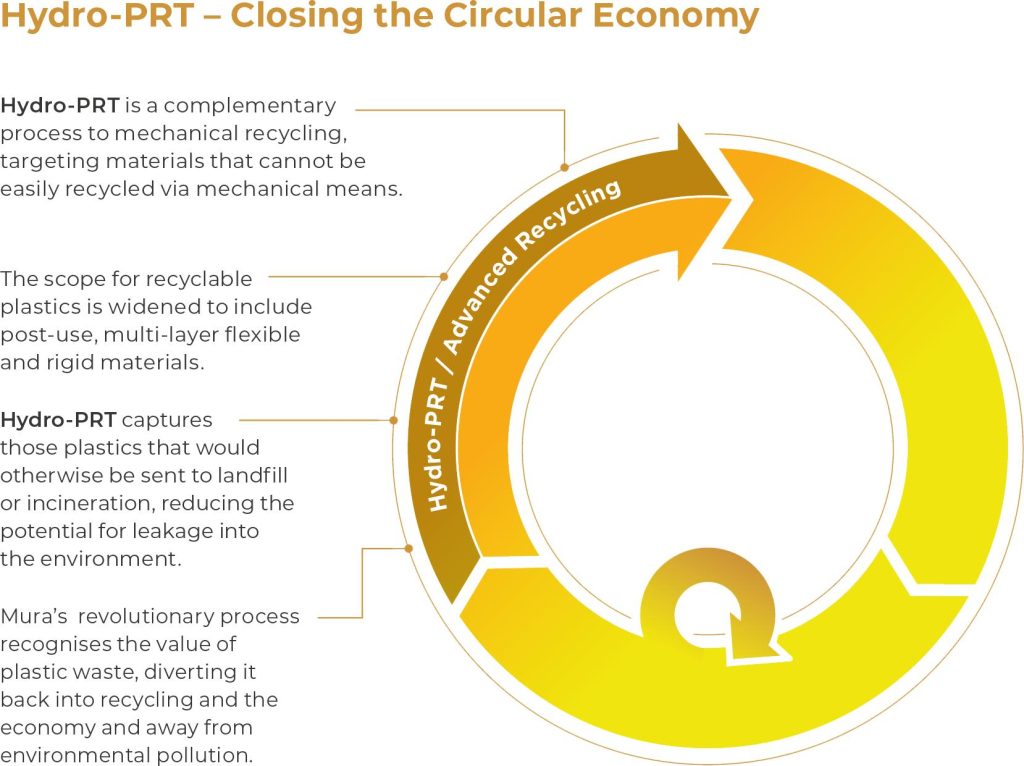

Target feedstock for Hydro-PRT® is plastic materials which cannot currently be recycled via traditional mechanical means, including flexible and multi-layered plastics. By capturing these materials and directing them into recycling and away from landfill and incineration, we close the loop on a circular economy, capturing lost value and protecting the environment from plastic pollution.

To keep up to date with our global roll-out and developments, please complete your details below: